Wandering

When I was born, my father was rector of the now-long-gone Saint Thomas Episcopal Church in Somerville, Massachusetts. It was on Washington Street near the Sullivan Square “T” Station; there is a Brazilian barbeque restaurant in that location now. It was a small parish, but I presume there was a pipe organ—all churches had pipe organs then. I was four months old when Dad was named the first priest for the new Episcopal mission of Saint John in Westwood, Massachusetts, just outside Route 128 (now I-95), which was the first circular perimeter commuter highway in the United States. We moved briefly to a rented house in Westwood, and in 1958, before I was two years old, we were ensconced in the brand-new rectory adjacent to the church building.

There was a pipe organ at Saint John’s from the start, with a juicy tidbit of American organ history to boot. It was built in 1959 by the Andover Organ Company, then owned by the thirty-four-year-old Charles Fisk. It had one manual, six stops, and a two-manual detached, reversed console, all mounted on a platform—a strange little setup until you realize that it was intended as the Rückpositiv of a larger two-manual organ, the Great and Pedal to be built later in a free-standing case as the parish grew and funds became available.

The mission building was a simple frame structure with a linoleum floor, and the organ sat down front on the left. The building was also designed to be expanded to greater glory, and that happened starting in 1963 when two towers were added with stained glass faces (I got bagged when at seven years old, I climbed to the top of the scaffolding surrounding the seventy-foot tower only to see my parents’ car coming up the road), and a rear balcony was built. My earliest organbuilding memory was seeing that organ hanging outdoors from a crane. The roof had been opened in two places and the organ, pipes and all, was hoisted to its permanent home. I’m a professional. Don’t try this at home.

Dad was called to be rector at the Parish of the Epiphany in Winchester, Massachusetts, in 1966. That is where I had my first experience playing an organ. A new organ by C. B. Fisk was installed there in 1974. I took organ lessons at the Episcopal Theological School in Cambridge, Massachusetts, on a Holtkamp organ installed when Charlie Fisk was an apprentice with Holtkamp, just three years before the Saint John’s organ. I continued my lessons at the First Congregational Church in Winchester on the new three-manual Fisk organ, went to Oberlin to wallow in the renowned fleet of instruments there, and went out into the world as organist and organbuilder.

I have worked for four organ companies including my own, I have served two churches as organist for a total of thirty years, and I have been director of the Organ Clearing House for twenty, a position that has had me in direct contact with hundreds of organs. I have played hundreds (thousands?) of organs in the United States, Great Britain, Europe, even on a Cavaillé-Coll organ in Antananarivo, Madagascar. My wife and I have traveled extensively in Greece where there are very few organs, especially on sailing vacations in the Ionian and Aegean seas, but while I could not get access to it, I laid eyes on a tiny pipe organ in a high balcony in a Roman Catholic church on the Island of Siros. I am thinking that our Greek trips might be the only times since my birth that I have gone more than a week without playing, hearing, or seeing a pipe organ. Until now.

As the Covid-19 pandemic started to break out in early March, we left New York City with extended family for our place in Maine. A few days before that, I visited an E. & G. G. Hook & Hastings organ built in 1872 (Opus 668) that has been in storage for ten years. My colleagues and I were pulling it out of the container to measure key components to prepare for laying it out in a new location. It was the last instrument I saw. It has been 117 days since I laid eyes on an organ.

Remembering

In April 2016, Wendy and I spent a long week in Great Britain. We sure saw a lot of organs on that trip. I loved seeing the fifty-two-stop Willis organ (1891) in the library of Blenheim Palace. Following the tour path through the building, one first sees the organ partially through an archway at the end of the vast room. The organ was built in the height of the Victorian Era, and it looks it, bedecked with opulent swirls and swoops of carvings and elegant inlaid decorations across the keydesk. Beautifully made mechanical stop actions are visible from the sides, as well as miles of lead tube for the pneumatic keyboard actions. Next to the organ hangs a framed photo of Henry Willis sitting at the console, apparently working on tonal finishing. The case had not been installed yet, and lots of the organ’s innards are visible.

Our host was Andrew Patterson who serves as a volunteer curator of the organ and plays many of the regular recitals. He pointed out a dent in the largest façade pipe of the C-side tower, close to twenty feet off the floor. The story goes that the palace was temporarily home to a school for boys during the Second World War, and the dent was the result of an indoor ball game.

When I was in high school, I was assistant organist at the First Congregational Church in Woburn, Massachusetts, home of E. & G. G. Hook’s Opus 283 (1860). George Bozeman was the organist, and he figured out how to create a position for me so I could be his regular substitute when he traveled for organ installations. The parish has diminished quite a bit over the years, but the grand organ is still in place hoping for restoration. It was in good shape for my time there, and I learned a lot from it.

I had agreed to accompany a concert of the all-elementary school chorus in late June, not long before my graduation. I attended a couple rehearsals, and it promised to be a fine event. One beautiful June Sunday, a couple of my pals came to church in Woburn to hear me play, and we took off for the beach after church. I got home that evening to phone messages wondering where I was. You guessed it. I missed the concert. Carl Fudge, the organist of Epiphany in Winchester, was in attendance because his daughter was in the chorus. He volunteered from the audience to mount the stage and to accompany the concert. I wonder if any readers have a lifelong blush from a moment like that.

In the summer of 1976, I worked for Bozeman-Gibson for a few months. The shop was just completing a one-manual organ for the chapel on Squirrel Island, Southport, Maine. John Farmer, long-time organbuilder in Winston-Salem, North Carolina, was my senior in the shop, and we would take the organ to Maine for installation. But first, over the Independence Day holiday, we installed the organ temporarily in the crossing of Boston’s Cathedral of the Holy Cross for Barbara Bruns’s performance of Handel organ concertos with the orchestra of the Handel and Haydn Society for the convention of the American Guild of Organists, held in Boston that summer. We worked hard through a couple nights getting the organ set up. In those days, the Orange Line of the Massachusetts Bay Transportation Authority (MBTA, aka “the subway”) ran on tracks elevated above Washington Street, and the trains roared past the dark cathedral all night. Other highlights of that convention included Farmer and me playing the appropriate parts in a piece for organist and two organbuilders by Martha Folts on and in the Fisk organ at King’s Chapel, and E. Power Biggs’s last public performance, Rheinberger with the Boston Pops Orchestra and Arthur Fiedler.

After the convention, we dismantled the organ and drove it to Maine, where we loaded it onto the Squirrel Island ferry, a small vessel a lot like a lobster boat—it took three trips to get the organ there. The only vehicle on the island was the superintendent’s ancient beat-up pickup truck, which took many trips up the dusty road from the dock to the chapel laden with organ parts. A cold beer never tasted so good.

The island was buzzing with news of a recent faux pas. The island is roughly equivalent to a condominium corporation where homeowners own shares of the island and contribute to its upkeep. They had recently banded together for the construction of a water tower that brought “city” water to the island for the first time, eliminating the reliance on quirky wells. With construction complete, the tank was left full of a cleaning solution, and it was the superintendent’s job to empty it at a specified time and fill it with water. So he did, forgetting to open a valve allowing air into the tank as the fluid drained, and the tank collapsed inward with a big bang.

During the job, we took the ferry back to town for an evening or two and followed islanders’ recommendations to eat at Lobsterman’s Wharf in East Boothbay, Maine. My historically informed ongoing Oberlin education was enhanced by a local country-western band sharing such gems as I Just Kicked the Daylights Out of My CB Radio (Google™ didn’t turn it up for me, I wonder if it was an original?) and Drop Kick Me, Jesus, Through the Goalposts of Life, written and made famous by Bobby Bare and easily found on YouTube, which I later learned was Bill Clinton’s favorite country song. Forty-four years later, almost to the day, I am sitting at my desk in Newcastle, Maine, on the shore of the Damariscotta River, about six miles upriver from Lobsterman’s Wharf. We have often gone there by boat, tying up at their dock where I can hear the echoes of those two songs.

Adjacent to Lobsterman’s Wharf is the Washburn & Doughty Shipyard, famous for the construction of huge powerful tugboats that service the ports between Boston and New Jersey and move cargo, especially fuel, over the same waters. In July 2008, John Schwandt, then professor of organ at the University of Oklahoma, was staying with us while preparing for a concert on the Kotzschmar Organ in Portland. On July 11, John and I were sitting on a rock on the shore of the river when we noticed a vast plume of smoke to the south. Washburn & Doughty was on fire. The Boothbay Register reported that a 121-foot articulate tug barge and a 92-foot “Z-Drive” tugboat under construction at the time were towed to safety by the heroic efforts of lobstermen from East Boothbay and South Bristol across the river. The shipyard was rebuilt so quickly that local suspicion had it that plans and financing were in place for replacing the building before the fire started mysteriously.

Just a month before that riverside chat, I returned from my first trip to Madagascar. I had traveled on an invitation from Zina Andrianarivelo, ambassador from Madagascar to the United Nations, at the behest of Marc Ravalomanana, the Federal President. The president was also vice-president of the Protestant church there, and in preparation for an important upcoming anniversary, had asked the ambassador to “go back to America and find an organ for this church.” The cold call I received from Zina was the doozy of a lifetime, and I agreed to meet him in New York to discuss it. I was sure I was the only organbuilder at work at the United Nations that day.

I have written before about the travel plans that included no details about hotels or even a flight home. Once in the country, my name would be on a list for notification when there would be a flight back to Paris. Otherwise I had no itinerary whatsoever. Of course, I was treated handsomely. My flight arrived after midnight, I was met at the airport by snappily dressed presidential aides, treated to drinks in the VIP lounge, and whisked forty minutes to the capital where I checked into a room in a four-star, French-owned hotel reserved in the president’s name. As I ventured into the hotel restaurant for breakfast, a server informed me that my driver would be out front in an hour. Richard, the driver with a big government car, took me to the church where I met the ambassador, was given a cell phone, and was introduced to church officials who would show me the dozen or so churches the president wished to enhance with organs.

I met Adolha Vonialitahina, a lovely young woman who had just graduated from Texas Christian University in a scholarship program instituted by the president. Adolha would be my translator and guide, so I had an entourage. The trip included many rich experiences, including a four-hour drive to Andasibe-Mantadia National Park where I saw lemurs in their natural habitat. We visited a church in Antananarivo (the capital city, colloquially known as Tanariv, or simply, Tana) where they showed me an organ in a non-descript plywood case. When I opened the fallboard I burst into tears. There was the familiar and distinctive gilded nameboard of Aristide Cavaillé-Coll. I saw a lovely organ by Merklin in another church, reminding me that Madagascar was a French colony until 1963.

As I returned to JFK Airport, my wife Wendy was leaving for a trip to Jordan with a friend. We were in the airport at the same time. She saw my flight from Paris arrive, but we did not see each other in person, two ships passing in broad daylight.

Delivering an organ to a church in Arlington, Massachusetts, in about 1985, a co-worker slipped on a stairway. When he grabbed wildly to steady himself, he pulled a fire alarm and the city responded with vigor. We called him Sparky after that. And working in an organ loft in Manhattan, I forgot to turn off the smoke detector beam. When I walked in front of it, the horns started blaring. This time it was a big deal because there is a large and active day school in the building, and the FDNY knows to respond with intent. Fire apparatuses filled the cross street and blocked both Park and Lexington avenues. There must have been thousands of people affected, most singularly the rector who was in the shower in the sixth-floor rectory and came to the street with wet hair wearing a cassock. That memory is filed away next to the trip to the beach in 1974.

Twenty years ago, the Calgary International Organ Festival was my host for a project. The Calgary Stampede is held each year on the Fourth of July, a huge rodeo festival celebrating the end of the roundup and castration of the herd. When they asked what I liked to eat, I said since I am from New England, I would pass on Alberta seafood. One fellow rubbed his hands together and smiled, and off we went to Bottlescrew Bill’s Testicle Festival. They don’t taste like chicken.

Bottlescrew Bill’s, the 1976 American Guild of Organists Convention, my trip to Madagascar, the delivery of the organ to Squirrel Island, the tugboat fire, the fire alarm in Manhattan, and the missed concert in Winchester all happened within a week or so of the Fourth of July. Today is July 6th. I wonder when I will see an organ again.

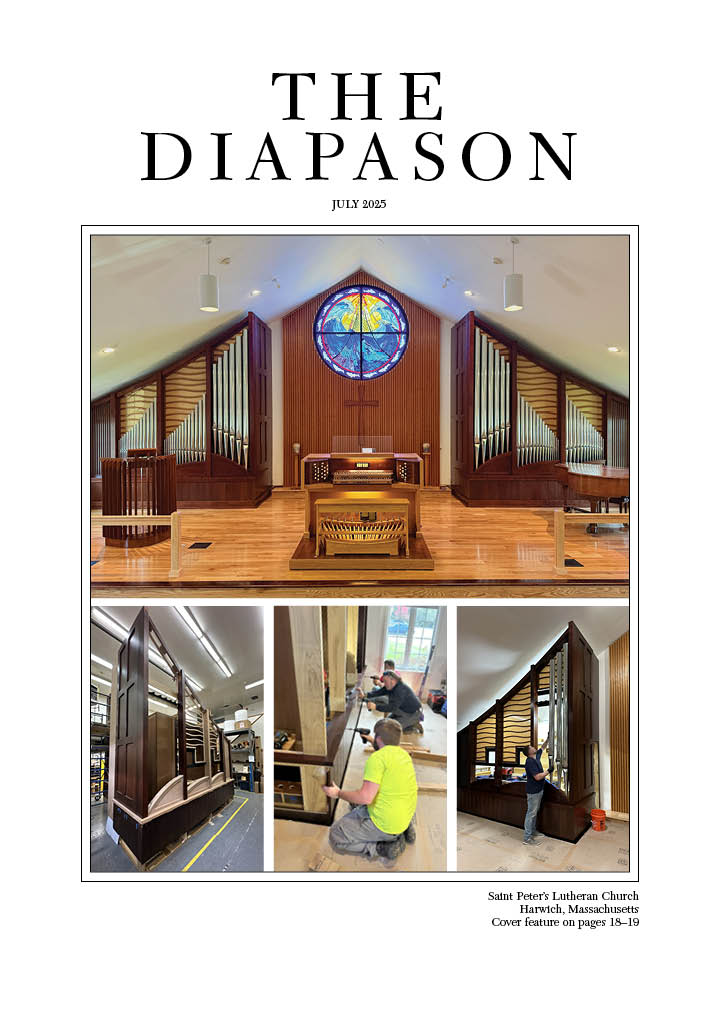

Photo: Squirrel Island organ. Photo credit John Bishop.