Randall Dyer & Associates, Inc., Jefferson City, Tennessee

First United Methodist Church, Lebanon, Tennessee

From the first time I walked into the church unannounced one day while passing through town and happened to meet Charlie Overton, the affable minister of music, I knew the possibility of building an organ for the First United Methodist Church of Lebanon, Tennessee, had the potential to be an organbuilder dream job. An equally nice and open-minded organ committee was receptive to suggestions and willing to travel to Lexington, Kentucky, to see our organ at the Cathedral of Christ the King. Whether it was due to that organ or the authentic Kentucky barbecue we had for lunch is debatable, but as we parted ways, I was pretty certain we were going to build them an organ. During the process, the minister of music changed, but no momentum was lost as the new man on the podium, Windell Little, was totally on board.

The church building hails from the 1960s, a handsome “contemporary” Georgian structure. The church’s M. P. Möller organ from the late 1920s had been moved from the old building by J. Alex Koellein, a late-in-life, but nevertheless capable organ technician who in a former life had been a station agent for the Tennessee Central Railroad, the track of which runs about two blocks behind the present Lebanon church building. He added several new ranks of well-made pipes and a new console in the move, but unfortunately, the entire instrument was installed in chambers on each side of the divided chancel.

From an organbuilder’s standpoint, we were struggling to come up with both a placement and a visual that would look good, project the sound well into the room, and stay in good usable tune. While cantilevered dual side chests were briefly considered, the fact that one chamber was on the east side of the room with the other on the west, both with three outside walls, meant that the pitch relationship of the pipes in those chambers would change as the day wore on and the sun moved around the chancel on the south end of the building.

Standing in the spray booth painting pipes for another job one day, a “visual” suddenly occurred to me. I went to the drawing board and penciled the idea over half of a large blown-up picture I had taken of the church’s chancel. That sketch was eventually converted by PipeShader, a professional organ visual designer, into a real-looking computerized image and presented to the church, where it was quickly accepted. But there was other work to be done before that could happen.

Friend and frequent organbuilding colleague Larry Sprinkle, who, like me, has an interest in trains and railroading, had decided to travel cross-country with me to the American Institute of Organbuilders convention in Concord, California. We would intentionally travel by car, so that we could follow the transcontinental railroads, Burlington Northern-Santa Fe, through Texas and New Mexico, on the westbound trip. This would carry us not only by the Grand Canyon, where resides a steam locomotive we had both known locally several years earlier, but by such iconic railroad places as Cajon Pass, descending into Los Angeles basin, and Tehachapi Loop, the latter crossing the mountains near Bakersfield. Along the way we stopped in Oklahoma City, a place to which I always find myself drawn when in the area, remembering the utter destruction of the federal building with huge loss of life, including children. Coming home, we followed Union Pacific on the northern route across Donner Pass, through Salt Lake City (remember the “golden spike”?), and on to Chicago, where we picked up some materials for the Lebanon organ in the van we were driving.

Despite the spray-booth brainstorm, Larry and I had not talked about the job, so he was surprised when, without explanation, I diverted off westbound Interstate 40 into Lebanon to look at the church. Besides being an organ person, Larry also has an engineering background. I took him into the building, where we walked around the room a few minutes, and then I said, “Can the (concrete block) walls on each side of the chancel window be knocked out?”

The very handsome stained glass central window is recessed about four feet to an outside wall beyond the front chancel wall, so that there is a hidden hall passing from one side to the other, for the convenience of the choir. The area above the hall was an enclosed floor-to-ceiling dead space on each side of the window, about 25 feet tall. In typical Larry fashion when he’s thinking, he quietly stroked his chin, walked around the chancel behind the walls, went outside to look at the building from that vantage, and after about ten minutes of pondering, said, “Yes; they aren’t structural. They can be removed.”

Apprehensive that the organ committee would think I had lost my mind, I nevertheless approached them with the concept of removing the walls and recessing the organ back into the gained space, sealing up the side chamber tone openings in the process. To their great credit, they immediately bought into the concept and engaged an architect to do the engineering.

Local building contractor Mike Walls, who had done other construction for the church, was engaged to do the work. While preparing the organ spaces, the carpet was replaced by hard flooring throughout the room, and the padded pews were refinished to their dark mahogany color, substantially improving the acoustics.

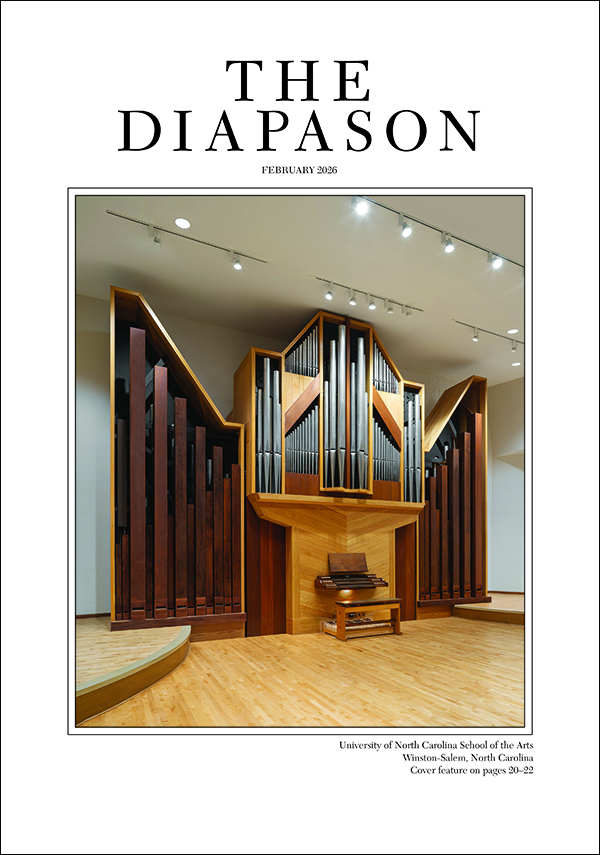

The false walls removed and the outside walls well insulated with glued-on Styrofoam, the new organ occupies the depth of the gained space. It is supported on long legs, so that the choir can still walk under it from side to side and enter the choir loft on the outside ends through doors that are part of the organ case. The structure of the organ is totally self-supported to the floor and relies on the building only to brace it. Built of heavy, medium-density fiberboard, painted to match the white pew ends, the lower organ cases serve as perfect reflectors for the sound of the choir, now located across the chancel instead of divided. And the medium density fiberboards make very effective enclosures for the Swell and Choir sections.

Pipes of the Pedal 16′ Principal and Great 8′ Principal, made of aluminum by Matters, Inc., are cantilevered from the structure of the organ to form the façade. Surprisingly, the total weight of the twelve longest pipes is only about 250 pounds on each side.

Several sets of the 1960s pipes added by Koellein were reused in the new organ, among them the Pedal Rauschquinte, made from the former Great 2-2⁄3′ and 2′ stops, as well as the 16′ Trombone. The 16′ Subbass, painted white to blend in with the walls and case, is also “previously owned” from our warehouse stock. The remainder of the flue pipes were made by Stinkens of the Netherlands with reeds by Oyster Pipeworks of Ohio. Bradley Jones, tonal director, voiced the flue pipes in our shop and was assisted in the final tonal finishing by David Beck. The pipes play on our own electro-pneumatic slider-and-pallet chests.

A couple of stops are of special interest: the Swell 8′ Geigen is a large string, almost Principal in scale, and serves as the basis of the Swell secondary ensemble. The Great Major Flute starts as a large-scaled Rohrflöte and becomes a Harmonic Flute in the upper registers, hence the Great Tremulant.

The mahogany drawknob console, also built in house and stained to match the pews, with bone and rosewood keys, is easily movable throughout the chancel on recessed casters and connects to the organ by one very small fiber-optic “wire” that quickly plugs in at two different locations. The relay system, also by Matters, features multiple memory levels, transposing, and record/playback capabilities.

Randall Dyer & Associates Opus 100 was completed in time for Christmas 2017. The opening concert in January 2018 by Andrew Risinger of West End United Methodist Church in Nashville was played to a room so full that the doors had to be locked because of fire occupancy regulations. A subsequent concert by Wilma Jensen was similarly well attended. And the two demonstrated that the organ can literally play anything that is put to it.

Though not a large instrument, the organ donors are happy, the musicians are happy, and the congregation sings their lungs out. For what more could an organbuilder dream?

GREAT—Manual II, unenclosed except as noted

16′ Bourdon (Sw)

8′ Solo Principal (Ped)

8′ Principal (façade, from low G, 70% tin) 61 pipes

8′ Major Flute (1–12 fr Ped) 49 pipes

4′ Octave (70% tin) 61 pipes

2′ Doublette (fr Mixture)

IV Mixture (70% tin) 244 pipes

8′ Trompette (Sw)

8′ Oboe (Sw)

Tremulant

8′ Grand Trumpet (Ch)

Chimes (existing)

Cymbelstern

SWELL (Manual III, enclosed)

16′ Bourdon 61 pipes

8′ Geigen 61 pipes

8′ Celeste (TC) 49 pipes

8′ Bourdon (ext 16′) 12 pipes

4′ Principal 61 pipes

4′ Spitzflöte 61 pipes

2-2⁄3′ Nasard 61 pipes

2′ Blockflöte 61 pipes

1-3⁄5′ Tierce 61 pipes

III Plein Jeu 183 pipes

16′ Oboe 61 pipes

8′ Trompette 61 pipes

8′ Oboe (ext 16′) 12 pipes

4′ Clarion (ext 8′) 12 pipes

Tremulant

CHOIR (Manual I, enclosed)

8′ Copula 61 pipes

8′ Erzähler 61 pipes

8′ Erzähler Celeste (TC) 49 pipes

4′ Koppelflöte 61 pipes

2′ Principal 61 pipes

1-1⁄3′ Quinte 61 pipes

8′ Clarinet 61 pipes

Tremulant

16′ Grand Trumpet (TC, fr 8′)

8′ Grand Trumpet 61 pipes (high pressure)

PEDAL

32′ Resultant (derived)

16′ Principal 73 pipes

16′ Subbass (existing) 56 pipes

16′ Bourdon (Sw)

8′ Principal (ext 16′)

8′ Subbass (ext 16′)

8′ Bourdon (Sw)

4′ Principal (ext 16′)

4′ Flöte (ext 16′)

II Rauschquinte (existing) 64 pipes

32′ Reed Cornet (derived)

16′ Trombone (ext Sw) 12 pipes

16′ Oboe (Sw)

8′ Trompette (Sw)

4′ Oboe (Sw)

8′ Grand Trumpet (Ch)

3 manuals, 32 ranks, 1,913 pipes

Builder’s website: www.rdyerorgans.com

Church website: http://lebanonfumc.com