Ortloff Organ Company, LLC, Needham, Massachusetts; Saint John’s Episcopal Church, Williamstown, Massachusetts

Rosemary brought the first box. It was plain brown cardboard, thin, waxed—the kind of container in which you take home leftovers from a restaurant.

The next day, Abby walked down the aisle with the second box, identical to the first. Each was brimming with snacks: cheese, apples, cookies, nuts. The week before, six of these empty boxes had been placed at the rear of the church, with instructions for volunteers to take one home and “provide enough goodies for five people for one day.” And, as if it really needed to be said, “The Ortloff Organ installation folks are grateful for your kind support.”

This all came about from a few closing words in one of the many emails between us and Saint John’s Episcopal Church in Williamstown, Massachusetts, as we were coordinating the installation of their new organ. Would we like snacks while we were installing our Opus 4 in March? Of course we would—who says no to snacks? Over the course of the two-week installation, we received six parcels, many with home-baked goodies, the kind that always disappear first at coffee hour. In this ministry of hospitality, these church members were directly feeding the organbuilders who were installing the instrument that would accompany worship at Saint John’s for their children, grandchildren, and great-grandchildren.

It is these moments we take away from installations, far more than the walkboard that didn’t fit or the strings that needed loudening. We remember, in ways figurative and literal, the moments that feed us in our work: hearing the gasps when parishioners first confront a field of organ parts spread across the pews, or see the organ case assembled for the first time, or, of course, watching the looks on their faces as they sing with their new organ for the first time.

While we know what feeds us, it is our job as organbuilders to learn what feeds each congregation: what each church needs, musically, to worship, grow, and experience God through singing. Like many Episcopal churches, Saint John’s is a boldly singing parish; the fine choir includes choral scholars from Williams College. As such, the menu for the organ was clear early on: support singing from both congregation and choir with warmth and color. The usual three-legged stool of stoplist, budget, and available space suggested an instrument on the small side. As we worked through these big-picture questions with the church, it became clear the challenge was not deciding the menu; it was finding enough room on the table.

Surrounded by the campus of Williams College in the Berkshire mountains of Western Massachusetts, Saint John’s fieldstone building is at one with its bucolic setting. Built in 1896, the church is of modest size, but with exquisite adornments: angel-headed winged hammer beams, a carved reredos with mosaics depicting Jesus and Mary, and a stunning collection of stained glass from the studios of Tiffany, La Farge, and Connick.

The space given for the organ is a chamber roughly six by eight feet on one side of the apsidal chancel, once housing Skinner’s six-stop Opus 792 of 1929. In 1965 M. P. Möller rebuilt the organ, adding an unenclosed Great in a cantilevered flower box. In this new iteration, half the instrument spoke down the nave and the other half into the chancel, resulting in a confusing and un-blending jumble. The poorly insulated chamber bedeviled organ curators’ attempts at tuning, though not nearly as much as the nearly nonexistent service access. When the Möller started failing, it became clear the time had come to start over.

Between fulfilling the musical needs of the parish and overcoming the infrastructural challenges of the space, the menu for the new organ was quite large indeed. However, at a mere twelve stops—truly the maximum possible—Opus 4 ends up at a happy sweet spot in terms of size. There is (at least) one of everything the organist could want: stopped flute, open flute, string, celeste, mutation, reed, diapason. And even at a dozen stops, the organ has a proper, independent chorus. An honest flexibility from these twelve stops was paramount as we designed the organ to serve the Episcopal liturgy. That said, the design still hews to strictures of good classical organbuilding, avoiding the temptation of excessive unification, in which an organ can appear to lose confidence in the conviction of its own content. Throughout, the successful accompaniment of singing was the ultimate goal.

To lead this hearty congregation, a rich, commanding Great chorus was essential. To take any guesswork out of the design, with the Möller still in place we voiced several dozen sample pipes to help determine scaling, general volume, and tone of each stop. Per our usual practice, the chorus is made of a high-lead alloy for warm, singing foundation tone and glittering, silvery upperwork.

The Swell mostly reuses pipework from the church’s previous instruments, carefully chosen to serve specific tonal needs. Broad strings provide foundation and color. The 4′ Principal, from the Möller’s Great, needed just a little nicking and cutting up to bloom into a lighter version of the new Great Octave. The Skinner 4′ Harmonic Flute does double duty as a perky piccolo, while the tapered Nazard spans flute and principal tone, allowing the Swell to offer at least something of a foil to the Great chorus.

The one new stop in the Swell contains the first metal pipes made in our shop: the 8′ Lieblich Gedeckt. This stop is modeled after those of English builder Thomas Lewis, using measurements we took from his 1895 four-manual organ at Albion Church in Ashton-under-Lyne on the east side of Manchester, England. As the organ’s only 8′ flute, it needs to fill both accompanimental and solo roles. The piquant, bell-like tone of these narrow pipes serves the latter admirably in the treble; the tenor and bass octaves are kept soft for unobtrusive accompaniment. Likewise, as the organ’s only reed, the Oboe straddles chorus and color reed territory. Chris Broome rebuilt and revoiced this vintage rank to do just that, mating it to a new 16′ octave as a climactic bass stop.

The major decision reached early on, together with the church and consultant Mike Brittenback, was to close up one of the two chamber openings and have all tone come from one direction. The importance of choral music in Saint John’s worship suggested that the existing chancel opening would be best, giving the choir benefit of direct sound. To create more space for the amount of organ we planned, we elected to build a proper case—the church’s first—for the Great, cantilevered into the room. The Swell would occupy the whole of the original chamber.

The existing chamber was stripped down to the exterior stone walls built up new: solidly constructed, properly insulated, and with ready access through an ample door. It was no mean feat fitting the whole of the Swell, plus Pedal Bourdon, into this narrow, deep chamber. Creative mitering ensured 8′ and 16′ pipes fit: the entirety of the full-length 16′ Fagotto is mitered to seven feet! We integrated an air circulation system to promote even temperature throughout the organ, which, together with modern insulation, ensures stable tuning at Saint John’s for the first time.

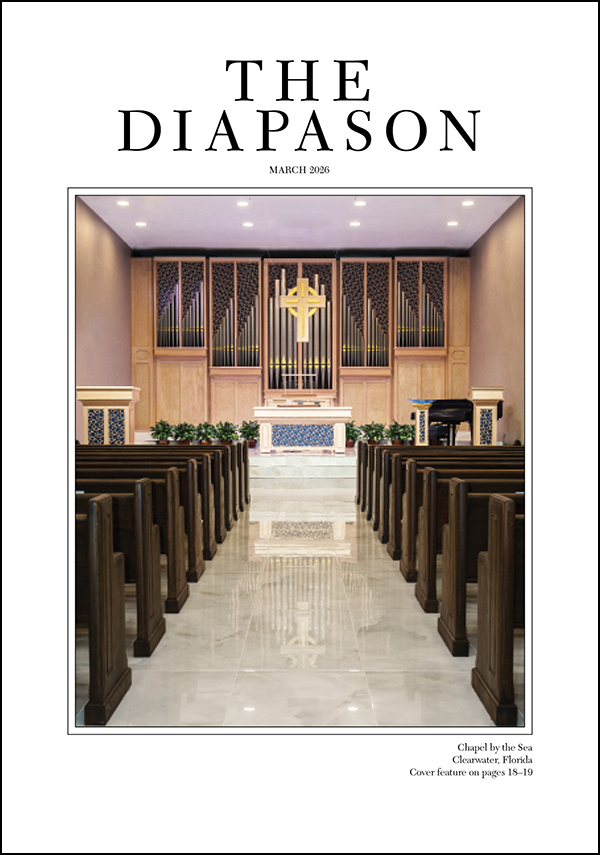

The organ’s case was a new challenge for us, as our previous instruments have been installed in mid-century modern buildings with case designs to suit. But Saint John’s village gothic setting provided an opportunity to turn to classic models. The chamber opening is tall and narrow, not always a good fit for a case. Taking the challenge in stride, we developed the design over many months with the Saint John’s committee.

The case is built of solid white oak using traditional joinery and moulding. It stands nearly fourteen feet tall, cantilevered on steel beams three feet into the chancel. Bass pipes of the Great Diapason, of heavy spotted metal, form the façade, their tops hidden behind delicate pipeshades of repeating gothic design. Having pipes on the front and both sides maximizes the tonal egress.

As with all of our instruments, the organ was fully erected in our shop to ensure proper fit and function. In mid-March, an open house brought more than 120 people, including a large group from Williamstown, to see and play the organ, tour the facility, and enjoy some good food and drink. In a wonderful moment, those gathered sang several hymns, as Saint John’s director of music Tim Pyper had thoughtfully brought copies of Hyfrydol and Laudate Dominum for all to sing.

Installation took place in late March, leaving nine of the twelve stops playable for Easter. Tonal finishing continued after Easter, with completion in May. The organ was blessed in a service of dedication by the Right Reverend Dr. Doug Fisher, Bishop of Western Massachusetts, on May 4. A formal dedication recital will occur this fall.

After we returned to the shop with our bellies full, a big bag of apples from the Saint John’s snack volunteers remained on our breakroom table and was consumed over the next week. It was a happy reminder of the hospitality showed us while in Williamstown. Feeding, whether it be friends or strangers, is after all one of the core messages of the Christian faith. As we look forward to the future of our organ at Saint John’s, it brings a smile to our faces to think of its helping to feed the congregation for generations to come.

Ortloff Organ Company staff

Bart Dahlstrom

Kelvin Deeming-Kent

Jonathan Hess

Pat Meaden

Dave Mitchell

Jonathan Ortloff

John Rogers

Installation and tonal finishing assistance

Jonathan Ambrosino

Peter Rudewicz

GREAT

16′ Lieblich Bourdon (Sw)

8′ Diapason 61 pipes

8′ Lieblich Gedeckt (Sw)

8′ Viola (Sw)

8′ Viola Celeste (Sw)

4′ Octave 61 pipes

2′ Fifteenth 61 pipes

1 1⁄3′ Mixture II–III 141 pipes

16′ Fagotto (Sw)

Great 16

Great Off

Great 4

Swell to Great 16

Swell to Great

Swell to Great 4

SWELL

16′ Lieblich Bourdon (TC, fr. 8′)

8′ Lieblich Gedeckt 61 pipes

8′ Viola 61 pipes

8′ Viola Celeste (TC) 49 pipes

4′ Principal 61 pipes

4′ Harmonic Flute 73 pipes

2 2⁄3′ Nazard 73 pipes

2′ Harmonic Piccolo (ext)

1 1⁄3′ Larigot (ext)

8′ Oboe 61 pipes

Tremolo

Swell 16

Swell Unison Off

Swell 4

PEDAL

16′ Bourdon 44 pipes

8′ Bourdon (ext)

8′ Lieblich Gedeckt (Sw)

8′ Viola (Sw)

16′ Fagotto (ext, Sw) 12 pipes

8′ Oboe (Sw)

4′ Oboe (Sw)

Great to Pedal

Swell to Pedal

Great to Pedal 4

Swell to Pedal 4

12 stops, 14 ranks, 819 pipes

Wind pressures

Great: 3.25′′

Swell: 5′′

Pedal Bourdon: 6.25′′

Builder’s website: ortlofforgan.com

Church’s website: stjohnswilliamstown.org

Photo credit: Jonathan Ortloff