Berghaus Pipe Organ Builders,

Bellwood, Illinois

St. Benedict’s Catholic Church,

Chesapeake, Virginia

From the builder

As most organ projects go, Berghaus Pipe Organ Builders’ instrument for St. Benedict’s Catholic Church proceeded at a rapid pace. The organ was completed just two years and one week after organist, conductor, author, and consultant to the parish Peggy Kelley Reinburg made initial contact with us in June 2012. From our very first meeting in which creative ideas were freely shared, our firm was enthusiastic about collaborating with Ms. Reinburg. Her insight into pipe organs, and in particular her thoughts on tonal design, proved to be invaluable resources. After long conversations with her and consulting her book, Arp Schnitger, Organ Builder: Catalyst for the Centuries (1982, Indiana University Press), we were confident that we could present an instrument with a heart of simplicity and clarity, rooted in North German tradition, that also possessed a distinctive voice, as our company has provided to clients for many years.

Following the signing of the contract in the fall of 2013, construction was executed over a six-month period, and the organ components were delivered to Chesapeake the day after Easter, 2014.Installation of the organ commenced over a five-week period, and tonal finishing took place over one month.

Our initial site visit revealed an existing south organ chamber that would eventually contain the Hauptwerk. For engineering and site preparation, the church contracted with Spiegel Zamecnik & Shah Inc. of Washington, D.C., to engineer the design and with Sussex Development Corp. of Virginia Beach, Virginia, to penetrate a tone opening for the existing chamber and create a second chamber on the other side of the rose window for the Schwellwerk and Pedal. Berghaus designer Michal Leutsch planned façade pipes and screens to complement the church architecture while hiding the dual enclosures. Initially, we intended to create a cloth screen barrier above the three pipe towers on each side. However, the logistics of creating such a screen prior to the arrival of the organ became impractical, and so its construction became part of the organ installation. Rather than use the ubiquitous grille cloth, we chose stamped metal screening, which would allow for better tonal egress.

Wind pressures are moderately low throughout, measuring 75 mm for the Hauptwerk, and 90 mm for the Schwellwerk and Pedal. This allows for a voicing style on classical lines, and yields pipes that work together with natural, unforced tone. Each chamber is equipped with a single horsepower Ventus blower, which provides ample and steady wind to all chests while keeping a simple yet effective winding plan for the entire instrument. Manual stops are primarily located on Berghaus slider and pallet windchests, which are controlled by Heuss electric pulldown magnets. Within each main chest is a large schwimmer, which provides stable wind. Pedal and unit ranks are located on electro-pneumatic windchests, also constructed by the Berghaus firm.Expression boxes are constructed from 1-3/4″ thick tongue and groove poplar, which allows for a wide range of dynamic possibility.

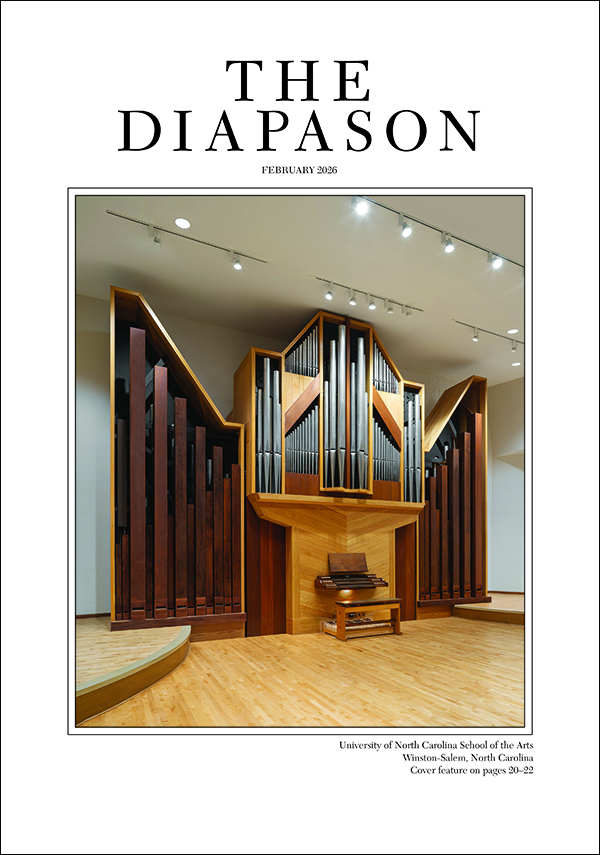

Both chambers are adorned by rift-cut red oak casework with accented trim, stained to match the church furnishings.The organ is played from a custom-built console of red oak and burled walnut. Keyboards are constructed of maple and walnut, and manuals utilize tracker touch. The combination action is controlled by the ICS-4000 system by Peterson Electro-Musical Products, and contains many features, including a piston sequencer and record/playback.

In the Hauptwerk, the principal chorus is moderately scaled and voiced without gimmicks to improve presence or warmth. Façade pipes are made of 75% tin and continue as such throughout the compass of the stop. The elevated position of the slider chest allowed us to treat pipes without fear that the choir would be offended by full registration, and at the same time, individual voices seem to bloom from within the chambers. The 8′ Hohlflöte is designed to act as a chameleon in registration, and is made from three distinct types of pipe construction: the bass octave is constructed as a stopped flute, the tenor octave is constructed as a Koppelflöte, and the upper octaves are constructed as a Hohlflöte. Deliberate voicing with attention to blending construction types was necessary to the successful finishing of this stop. The result is a flute that morphs well with many registrations. The Hauptwerk mutations are scaled to match the Mixtur IV–V and provide the light clarity of a Sesquialtera, thus providing a Germanic cornet décomposée for the division. In our shop, Berghaus constructed a Bourdon of poplar as our manual 16′ tone, and provided an 8′ Trumpet, which is voiced as a blending reed. Shallots are tapered German and provide warmth and fullness.

Schwellwerk flues are voiced full to support the generosity of the large scale mutations. Strings are made from 75% tin, and are generously scaled to provide adequate foundation tone, while also giving a satisfying sizzle that clarifies homophonic passages found in many pieces of Romantic and 20th-century repertoire. The 8′ Rohrflöte is scaled with large diameter chimneys, which are fully 1/3 of the diameter of the pipe.Together, these foundation stops provide remarkably solid grounding to the division. Once again, the substantial scaling of the mutations provides a powerful and nasal French-sounding Cornet. The Krummhorn is scaled generously to provide fullness to the mutations and is also available in the Pedal at 4′ pitch. The Oboe is designed with a French parallel shallot and is voiced moderately to blend well with the mutations. The Cromorne is scaled and voiced to provide fullness throughout the register.

As is often the case, available space made the luxury of a full and independent Pedal out of the question, and we therefore chose to unify the major principal and flute of the division. The pipes of the 16′-8′-4′ Principal wander back and forth between the Schwellwerk chamber and façade, which contains notes of the 8′ Octave. The bottom twelve notes are made from zinc and use interior Haskell tuners. The façade portion and above are made from 75% tin, as is the Pedal Mixtur. The 16′ Subbass is generously scaled, and was constructed of poplar by Berghaus craftsmen. The 16′ Fagott is made with pine resonators and used an historic Schnitger shallot with very wide reed tongues. The sound of this stop seems to have equal parts fundamental and harmonic development, and so it lends itself well to a broad spectrum of repertoire.

Overall, the organ’s resources create a myriad of tonal combinations, each at home announcing or complementing chant during High Mass, or in performing repertoire from Bach to Distler, from Couperin to Alain. Having both chambers enclosed further enhances the tonal palette and increases its flexibility as an accompanying instrument.

The organ was blessed on August 22 by Msgr. Walter Barrett, followed by Holy Mass in the Extraordinary Form in honor of the Immaculate Heart of Mary with Rev. Neal A. Nichols, FSSP, presiding. Peggy Kelley Reinburg served as organist and Jeanne Dart, director of music, led the choir. A dedicatory recital will be performed on November 22 at 3:00 p.m. by Crista Miller, director of music and organist at the Co-Cathedral of the Sacred Heart in Houston, Texas.

The entire team at Berghaus Pipe Organ Builders is extremely grateful for the collaborative efforts of everyone involved in the organ project. In particular, we appreciate the support we received from Fr. Nichols, Jeanne Dart, members of the choir, and parishioners who assisted in the unloading and various stages of installation. Berghaus Pipe Organ Builders’ sincerest gratitude goes out to all who helped make this a truly exciting and rewarding project. Soli Deo Gloria!

—Jonathan Oblander, Tonal Designer & Kelly Monette, Head Tonal Finisher, on behalf of the entire Berghaus Pipe Organ Builders team

From the consultant

After accepting the challenges of serving as organ consultant for a project with the all-too-common and severe limitations of the potential funding base, of being engaged after a new church structure was beyond any major architectural changes, and of having the responsibility of educating the clergy, the musicians, and the congregation regarding the advantages of committing to a pipe organ, I began to become aware of the positive realities of the project at St. Benedict’s Catholic Church in Chesapeake, Virginia.

First, it was revealed that the pastor, the Rev. Neal A. Nichols, FSSP, and the director of music, Jeanne Dart are both from Richmond, Virginia, my own hometown; and then we discovered we all had been educated, though for different lengths of time, at St. Benedict’s Elementary School! As we began to converse and to follow the natural order of organ consulting, I began to learn of the freedom I was being offered to guide my ninth organ project through its total evolution with no artistic constraints. Financial constraints can cause you apoplexy, but creative hamstringing can damage your soul!

The goals of this project were:

1) An organ built by a distinctive builder without financially drowning the parish

2) An organ that could support the numerous schools of organ and choral literature while underpinning the rich liturgical heritage of the Latin Mass

3) The creation of an instrument with its own identity, possessing the silvery sheen of a Baroque North German instrument yet supported by an enveloping warmth capable of bringing the worshippers and listeners to the depths of faith and to the heights of emotion

4) A Hauptwerk Prinzipal chorus that would make the congregation want

to sing

5) Provision of four primary reed stops: Krummhorn 8′, Hautbois 8′, Trompete 8′, and Fagott 16′, and of two Cornets décomposé, one scaled and voiced in the French manner and one in the German

6) Consistent nomenclature for the instrument

7) A beautiful encasement and console, which also would be visual works of art

8) Key and stop actions that would enable a marriage of the instrument and musician and also provide a comfortable playing and conducting situation. Mechanical action was desired, but eventually that preference had to be abandoned due to existing gallery design and spatial limitations.

After preliminary visits onsite with five major American mechanical-action builders and two builders known primarily for their other actions, the fact of a too-shallow gallery for an independent encasement and inadequate space for any future choir growth, coupled with cost comparisons, eventually were the deciding factors. The selection of a builder was also made difficult because of my personal acquaintances and friendships with all but one of the builders represented! Ironically, Berghaus Pipe Organ Builders was the only firm with which I had not had a previous connection; and after performing a recital on their instrument for St. John’s Episcopal Church, Norwood Parish, in Chevy Chase, Maryland, for the Northern Virginia and Potomac AGO chapters, I was convinced that the firm should be considered.

Every memo I wrote based on involvement with organs and organ building throughout my career and every wish included on my organ “bucket list” has been a consideration in consulting on this particular instrument. The lack of funding for three manual divisions resulted in enclosing both manual divisions and allowing console space for a third, a Rückpositiv, which it is hoped may be added someday. If it is not, the disposition of the organ as it stands has already created the illusion of the presence of a third manual division.

The opportunity of meeting at the workshop the majority of craftsmen who participated in this project and the pleasure of building a working relationship with them during the installation have been added delights. I have enormous respect for so many, especially those who have added to my deeper understanding and enjoyment of this facet of our beloved profession. I have only the utmost respect for the director of engineering and operations, Michal Leutsch, and for the tonal gurus, Kelly Monette, head tonal finisher, Jonathan Oblander, tonal designer, and Steven Hoover, tonal finisher and reed specialist. The gorgeous console with its burled walnut music desk and stop jambs is the exquisite work of console artist Jordan Smoots. Transformation of thousands of components into the organ as an entity was due also to the skilled work of Joe Poland, Ron Skibbe, Mitch Blum, Eric Hobbs, Kurt Linstead, and Casey Robertson. The administrative coordinator, Dawn Beuten, is embracing her new role in the company with enthusiasm; the firm’s office manager for six years and newly named vice president, Jean O’Brien, is the epitome of organization, efficiency and graciousness; and Brian Berghaus, president, leads the firm with admirable business acumen and a firm hand, peppered with a calming sense of humor, in his journey to maintain the integrity of the history of organ building while introducing the best of new technological developments to this art.

—Peggy Kelley Reinburg

Organ Consultant

All photos credit Deborah P. Spidle except as noted