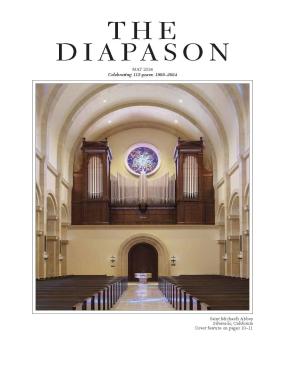

A. E. Schlueter Pipe Organ

Company, Lithonia, Georgia

New York Avenue Presbyterian Church, Washington, D.C.

The rich history of the New York Avenue Presbyterian Church is intertwined with the history of the United States, as it has played an important role during many crucial junctures of our history. The church traces its heritage to Scottish artisans who worshiped on the grounds of the White House as it was being constructed in the 1790s. As a regular worshipper during the Civil War, President Abraham Lincoln rented his own pew. From the early twentieth century it became customary for presidents to attend services on Lincoln Day and sit in Lincoln’s pew. Eighteen sitting presidents have worshipped at New York Avenue Presbyterian Church, and the cornerstone of the present church was set by President Truman.

Reverend Dr. Peter Marshall preached many famous sermons to a large national audience during World War II. During the annual Lincoln Day service in 1954, the Reverend George Docherty preached a sermon entitled “One Nation Under God,” calling for the addition of the phrase “under God” to the Pledge of Allegiance to the flag. The congregation that day included President Eisenhower, who, with his friends in Congress were prompted to add the phrase to the Pledge of Allegiance. Dr. Martin Luther King preached from their pulpit during the 1960s civil rights struggle. This church has long had social justice and responsibility at its very core, which cannot be adequately summarized in just a few lines.

I want to thank the church leadership, musicians, and members of the organ committee for their unwavering support of the Schlueter firm and me. So often when I had an idea, or desired to consider a change, the response invariably was “You are the organbuilder—we trust you. Do what you think is right.” Their measured dialogue, input, and trust were vital in the creation of this instrument and allowed our best work to flourish. I would also like to thank Texas organbuilder Mac Range, who served as a consulting resource between the church and organ company.

During my first visit with the church, I met with Pastor Roger Gench, director of music Dr. Stan Engebretson, and organ committee chairman Douglas Porter. I have to confess that at this meeting (being unfamiliar with the church and its instrument) my first inclination was to see if it would be possible to preserve the extant Skinner. However, after study of the organ, it became clear that the instrument was Aeolian-Skinner largely in name only, with the additional work of at least five other organbuilders. The church was considering the correct course in pursuing a new instrument.

The original organ built by John Brown in 1874 was rebuilt into a new instrument by the E. M. Skinner firm in the 1920s. Then in the 1950s the organ was enlarged and moved to the present church by Aeolian-Skinner. In the ensuing years there were various other additions to the organ and a replacement console. The organ chassis was a collection of E. M. Skinner, Aeolian-Skinner, and supply house actions—parts and pipes that were very much showing their age and were at the point of requiring rebuilding or replacement.

The placement of the former organ was in a rear gallery location. Often this location can be a benefit; however, in this church architecture it was a significant detriment. The organ was laid out with the Choir division in a pit below the rear choir gallery. The Swell division was stacked above the Choir division, with a Great division in front of this and a contemporary Positiv division flown over the Great chests and directly in front of the Swell chamber. The result was tone trap upon tone trap. The significant overhang of the balconies relative to the main sanctuary floor created even more sound traps. Add to that pew cushions on the main floor and the gallery. The result was that the organ started out bottled-up and fighting to speak from its location, and the sound that did get out was eaten up in the room and did not provide adequate support for congregational accompaniment.

Prior to our involvement, the church sought out the opinions of a variety of organists. The venerable organist, composer, and former Washingtonian, Dr. Douglas Major, served as an adviser and consultant to the project. He recommended that the organ and choir should be relocated to the front of the church. This simple act of forthrightly suggesting an alternate location for the organ and choir cannot be understated. His vision and recommendation are to be applauded, and as a builder, I consider the placement suggestion the single most important contribution to the success of this instrument.

In designing a major new element for the church chancel, we committed to the careful inclusion of elements from the church architecture. It was especially important to balance the visual beauty of the organ case with the Celtic Cross, retaining it as the central visual element in the room. We paired brushed zinc façade pipes with Lyptus® wood for the organ case. The choice of this wood species was influenced by the history of the church and its continuing social consciousness, including responsibility to the environment. As a sustainable, plantation-grown lumber, Lyptus® provides a beautifully grained wood that finishes well and complements the older walnut that is in the church furnishings, without adding to the deforestation of a native species.

It was interesting to see the expression of many of the church members the first time they saw the organ case. Incorporated into the organ casement is Isaiah 6:3, “Holy Holy Holy Is The Lord of Hosts The Whole Earth Is Full of God’s Glory,” and 1 John 4:7, “Beloved Let Us Love One Another For Everyone Who Loves Is Born of God And Knows God.” These scriptures, carved in mahogany panels that were gilded and polychromed, became visual reminders of our responsibilities in faith as organbuilders and servants of the church.

In designing a new specification that would incorporate some of the existing organ resources, a detailed study of the organ stops was conducted. It became evident that there had been a large degree of re-use and re-tasking of pipework during many different eras. There were opus numbers on pipework that were not attributable to either Skinner company or John Brown, but that did have marks from the E. M. and Aeolian-Skinner voicers and had been relabeled with inked opus numbers. Some of the pipework had been re-tasked multiple times. A good example was a 13⁄5′ Tierce in the Swell that had been a Great 4′ stop, prior to being a Swell 2′ stop, before becoming a 13⁄5′ Tierce. With rebuilding upon rebuilding, and stop reassignment and repitching, the organ had collected eight harmonic flutes of various pitches and significant scaling problems as they related to other organ stops. Scaling and voicing issues were scattered throughout the instrument among all stop families. Other peculiarities could be found in the Gemshorn, Erzahler, and Flauto Dolce. All of these stops, while differing in nomenclature, shared the exact same scaling, halving ratio, and mouth width. The Salicional and Voix Celeste in the Swell had been deslotted in a former life and various replacement pipes added to these ranks. The majority of reeds in the organ used French shallots, and these reeds provided a very brittle timbre in the church acoustic.

The organ did have many individual beautiful sounds, but they did not coalesce into a unified ensemble. Additional “diamonds in the rough” included the 8′ Clarinet and the 8′ Vox Humana, which dated from the John Brown organ and had been originally retained by

E. M. Skinner and later Aeolian-Skinner. There was clearly an aural reason these stops made the passage of over one hundred years and through the hands of several organ companies. When we studied the construction of these and other stops, and worked with voicing samples in the church, there was no question that these select stops had to be retained, albeit in different roles and/or registers.

Certainly it was clear that less could be more. The organ had grown to over 72 ranks over the years, attempting to overcome issues with the organ placement, room acoustic, and pipe scaling. During the organ removal, we discovered that the organ actually started to sound significantly better after over one-third of the resources had been removed, leaving fewer pipes and chests to occlude the pipe speech. We also moved pipe samples from the rear chamber location to the proposed chancel location. This proved invaluable as we considered the specification design, pipework scaling, and wind pressures.

During the church’s study of our firm, there were several visits to the Schlueter organ (III/47) at First Presbyterian Church in Savannah, Georgia. This instrument, featured in the April 2006 issue of The Diapason, was patterned loosely around the formative specification designs of early American Classicism. We allowed the English influence of American Classicism to flourish in this specification, with a nod toward the romanticism of early American twentieth-century tonal design. While not desiring a direct copy, there was an overall approach to specification and voicing style in the Savannah instrument that was the type of sound that embodied the core of what the church wanted for choral and congregational accompaniment.

The initial specification tendered had 58 ranks over three manual divisions and pedal. Later this grew to 62 ranks with donations made by the Schlueter family. We provided these additions outside of the contract budget because, as artisans, there were several stops that we personally wanted to include in this organ, including a second set of strings in the Swell division, the Great mutation stops, and other changes and stop substitutions.

Each division was designed around an independent 8′ weighted principal chorus. The divisional choruses, while differing in color, are designed to compound one another as a unified whole. The enclosed divisions were designed to be foils to the Great division, to provide weightless accompaniment for choral work, support repertoire, or massed in support of Romantic or transcription repertoire. The strings, when taken as a whole compounded entity, allow the organ to feature a divided string organ division located between the Swell and Choir divisions to be companioned by means of couplers. Considering the stoplist design and room acoustic, we chose to employ reeds with English shallots and voicing practices. Built with Willis tuba shallots, the 16′/8′ Tromba on 16 inches of wind pressure serves as the solo reed. Being enclosed in the Choir expression box allows full dynamic control of this heroic reed.

The organ is built with a steel and wood structure encased by the organ façade and millwork. The lower level of the organ contains the Swell and Choir, while the Great and Pedal divisions of the organ are located in the upper level.

Our firm built electro-pneumatic slider chest actions of the Blackinton variety, with our electro-pneumatic primary design. This type of chest action has the ability to operate over a wide pressure range without repetition problems or pressure limitations. Electro-pneumatic unit chests were provided for all large bass pipes, offset chests, and reeds.

In addition to the frontal expression shades, we designed louvers for the sides of the organ case that open rearward into the corners of the balcony. This was to purposely focus some of the organ energy into the gallery. With the removal of the soft pew pads, this area is used to coalesce the organ sound and maintains the sonic energy in the upper portion of the room, giving an impression of a longer reverberation time than the room actually has. Additional enhancement to the room acoustic came from removal of carpet, which was replaced with natural cork.

The resources of the organ are controlled by a three-manual drawknob console. Built in the English style, the console sits on a rolling platform to allow mobility. The console exterior is built of Lyptus® with an interior of ebonized walnut and ebony. The console features modern conveniences for the performer, such as multiple memory levels, programmable crescendo and sforzando, transposer, MIDI, and the ability to record and play back performances.

With new pipework, existing pipework, and changes to room acoustics, it was decided early on that all of the pipework would be voiced at the church. New pipework was only prevoiced to allow full latitude with cut-ups and any required nicking. All of the samples were set in the chambers on their windchests. A portable voicing machine was installed to the side of the chancel and all of the pipes were voiced prior to their installation in the chambers for final voicing and tonal finishing. Voicing an organ in this manner is quite literally a process of months, involving the movement of thousands of pipes, but was the only way to achieve the results we wanted. An organ of this scale and scope, with this amount of raw voicing work to be done onsite, required a large team. This effort was accomplished by Daniel Angerstein, Peter Duys, Lee Hendricks, Gerald Schultz, and Bud Taylor. It becomes a rote line from the articles of our work, but again I want to single out Dan for his contributions. Over the weeks and months of tonal work, he faithfully led our team’s tonal finishing efforts. He worked to patiently bring forth the voices as they had been planned and envisioned. Indeed, his fingerprints adjoin our own on this instrument.

The building and installation of a pipe organ is a monumental undertaking. The title “organbuilder” presumes long hours, travel, and the temporary suspension of personal lives. This year, in addition to rebuilding projects, A. E. Schlueter Pipe Organ Company built six new instruments. Our firm is so blessed to have the dedicated staff whom I proudly call my colleagues. I would particularly like to mention our management and road crew, including Arthur Schlueter Jr., Marc Conley, John Tanner, Shan Dalton, Marshall Foxworthy, Patrick Hodges, Jay Hodges, Wilson Luna, Rob Black, Pete Duys, and Bud Taylor for the untold hours of travel and work that they put into these projects. These are but part of the Schlueter Organ Company; a full roster of our staff and additional information on our firm and projects can be viewed at <www.pipe-organ.com> or by writing A. E. Schlueter, P.O. Box 838, Lithonia, GA 30058.

I have heard the collective work of organbuilders described as “stained glass for the ears.” As I thought about this, I considered New York Avenue Presbyterian Church, which is known for its sacred and secular stained glass windows, chronicled in the book Stories in Stained Glass (1998, Foster, Boswell, Hunter). To paraphrase the foreword by George W. Bergquist: “Generations from now, when the stained glass windows will have acquired the patina of time, they will continue to demonstrate that visual beauty of their sort powerfully reinforcing preaching, testimony and prayer.” How beautifully phrased. It is our sincere wish that our work will be an aural complement to the visual one as our instrument acquires the “patina of time.”

—Arthur E. Schlueter III

Artistic and Tonal Director

A. E. Schlueter Pipe Organ Company

3 manuals, 62 pipe ranks

GREAT

16′ Violone (extension)

8′ Principal

8′ Violone

8′ Gemshorn (CH)

8′ Gemshorn Celeste (CH)

8′ Bourdon

8′ Harmonic Flute

4′ Octave

4′ Spire Flute

22⁄3′ Twelfth

2′ Super Octave

13⁄5′ Seventeenth

11⁄3′ Fourniture IV

2⁄3′ Scharf III

8′ Trumpet

8′ Tromba Heroique (CH)

Chimes (digital)

Tremulant

SWELL

16′ Lieblich Gedeckt (extension)

8′ Principal

8′ Rohr Flute

8′ Viola

8′ Viola Celeste

8′ Salicional

8′ Voix Celeste

4′ Principal

4′ Wald Flute

22⁄3′ Nazard

2′ Octavin

13⁄5′ Tierce

2′ Plein Jeu Mixture IV

16′ Contra Oboe (extension)

8′ Trumpet

8′ Oboe

8′ Vox Humana

4′ Clarion

Tremulant

Swell to Swell 16

Swell Unison Off

Swell to Swell 4

CHOIR

16′ Gemshorn (extension)

8′ Weit Principal

8′ Holzgedeckt

8′ Gemshorn

8′ Gemshorn Celeste

8′ Flauto Dolce

8′ Flauto Dolce Celeste

4′ Principal

4′ Koppelflote

22⁄3′ Nasat

2′ Schweigel

13⁄5′ Terz

11⁄3′ Quint

2′ Choral Mixture III

8′ Clarinet

16′ Tromba Heroique (extension)

8′ Tromba Heroique

4′ Tromba Heroique (extension)

Zimbelstern

Harp (digital)

Tremulant

Choir to Choir 16

Choir Unison Off

Choir to Choir 4

PEDAL

32′ Violone (digital)

32′ Bourdon (digital)

16′ Principal

16′ Violone (GT)

16′ Gemshorn (CH)

16′ Bourdon

16′ Lieblich Gedeckt (SW)

102⁄3′ Quint

8′ Octave (extension)

8′ Violone (GT)

8′ Gemshorn (CH)

8′ Bourdon (extension)

8′ Gedeckt (SW)

4´ Choral Bass

4´ Cantus Flute (GT)

22⁄3′ Mixture V

32′ Contra Trombone (digital)

32′ Harmonics (wired cornet series)

16′ Trombone (CH)

16′ Contra Trumpet (GT)

16′ Contra Oboe (SW)

8′ Tromba (CH)

8′ Trumpet (GT)

4′ Clarion (GT)

4′ Cremona

Inter-manual couplers

Great to Pedal 8, 4

Swell to Pedal 8, 4

Choir to Pedal 8, 4

Swell to Great 16, 8, 4

Choir to Great 16, 8, 4

Swell to Choir 16, 8, 4

Cover photo: Dr. Stan Engebretson