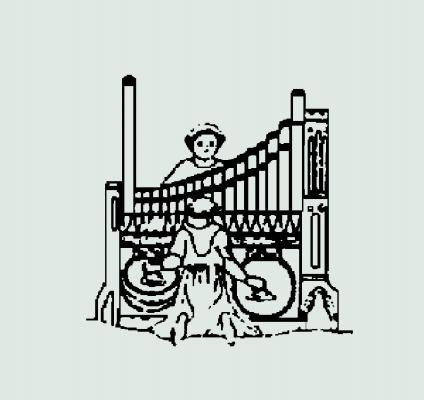

Key for the cover illustration

1. Original factory building, 158 Woodland Street. Occupied from 1899–1937.

2. Opus 2, Sweetest Heart of Mary Church, Detroit, 2 manuals, 20 stops. Still in regular service.

3. Opus 500, Panama-Pacific Exhibition, San Francisco, 4 manuals, 121 stops. Damaged in a 1989 earthquake, it remains in storage awaiting completion of restoration and installation.

4. Opus 2536, Trinity College Chapel, Hartford, 3 manuals, 62 stops.

5. Opus 2719, Our Lady of Czestochowa, Doylestown, Pennsylvania, 4 manuals, 65 stops.

6. Opus 453, The Organ Pavilion, Balboa Park, San Diego, 4 manuals, 62 stops.

7. Opus 323, City Hall Auditorium, Portland, Maine, 5 manuals, 124 stops.

8. Opus 2768, St. Mary’s College, Moraga, California, 4 manuals, 68 stops.

9. Opus 2782, Fountain Street Church, Grand Rapids, Michigan, 4 manuals, 139 stops.

10. The “new” factory building (1937), as expanded several times.

Center: The Austin Universal Airchest logo, including the crest with the motto: Scientia Artem Adjuvat. The motto and crest are said to have been the design of former Austin employee Robert Hope-Jones.

Background: The background is a blueprint, Opus 2786, Assumption Church, Westport, Connecticut.

The first Austin milestone:

1893—the first instrument

The Austin story begins like so many tales of European emigration. It was in the year 1889 that young John T. Austin sailed for the shores of the new world with a man he met who was visiting England (the Austin family native soil) and was returning to California. The Austin family was considerably well off: Jonathan Austin (the father) was a “gentleman farmer,” whose hobby was tinkering with organs and organbuilding. During the voyage, all of John’s money was liberated from his person before arriving in New York, presumably the result of the kindness of his traveling companion!

Penniless, he used his extraordinary wits to find his way to Michigan, and was immediately hired by the Farrand & Votey firm in Detroit. In a few years’ time, he had become plant superintendent, and in his free time he developed a concept for a new type of windchest. After building and servicing bar and slider (tracker organ) windchests, and certainly seeing many of the new electro-pneumatic actions coming on the scene, he was convinced that there must be a better way. The folks at Farrand & Votey were not interested, so in 1893 he built and sold a new organ that he built at the Clough & Warren (reed organ) plant.

His concept was innovative, because you could simply walk right into the windchest (he called it an airbox) and service the complete mechanism. Inside the airbox of many of these early instruments were also the motor for the bellows and the electric (direct current) generator. He started selling these new instruments with alacrity. It is an often-held belief that Austin organs have tracker-like lifespan, and this is evidenced by the fact that several of these early instruments, Opus 2 from 1894 for example, continue to play well year after year.

A discussion of the Austin mechanism would easily consume an entire volume, but in digest form, the organ utilizes one manual motor (primary note action) for each note, or key, in a division, and one stop action motor for each stop on a main windchest. The valves under each pipe are not leather pouches, such as one might find in a Skinner, Möller, or other electro-pneumatic instrument, but in an Austin, they are simply mechanical valves connected by wooden trackers (yes, trackers!) to the manual motor for each particular note. This mechanism is reliable and inherently self-adjusting. Springs and felt guides allow wild changes in humidity and temperature with no degradation in performance. The whole concept is, in a word, brilliant!

In 1899, perhaps the apex of the American Industrial Revolution, John T. Austin was just 30 years old when he moved into the facility on Woodland Street in Hartford, Connecticut. Legend has it that that the crew (including JTA) was installing the organ at the Fourth Congregational Church (Opus 22, now the Liberty Christian Center) when the factory in Detroit burned to the ground. Actually, John T. Austin was in Woodstock, Ontario, supervising the construction of the first and only Austin organ constructed by the Karn-Warren Company. The date of the fire was February 2, 1899 (the feast of Candlemas!). On March 31 of that year, the Austin Organ Company was incorporated in the state of Maine. The company actually signed a contract for a new organ on March 1 of that year and rented factory space in Boston—just down the street from the first, soon-to-be Skinner organ factory. The following August, the board of directors authorized the acquisition of the Hartford facility.

The business moved along quickly. It would be safe to say that most instruments of this period were of moderate size; literally dozens of three and four-manual instruments were delivered between 1900 and 1915. This was the point in Austin’s history when some rather significant and interesting instruments were installed. For example: Opus 323, The Kotzschmar Memorial Organ (www.foko.org) was built for the City Hall in Portland, Maine. It was one of the first municipal organs installed in the country. The organ has been played and maintained with loving care. A handsome, new five-manual drawknob console was built for the organ by the Austin firm in 2000.

This organ was followed a few years later by Opus 453, the Spreckels Organ in Balboa Park, San Diego, on New Year’s Eve, 1914. The largest and most renowned outdoor organ, it was the gift of businessmen John D. Spreckels and his brother Adolph B. Spreckels. The organ continues to be heard in regular concerts and events. Dr. Carol Williams retains the position as Municipal Organist, performing regularly to hundreds (www.sosorgan.com). This organ was originally built for the Panama-California Exposition, before being re-gifted to the city.

Meanwhile, up the coast in San Francisco, the Panama-Pacific Exposition in San Francisco would open just two months later and run concurrently with the San Diego event. Austin was chosen from a list of about 31 builders to construct the organ for this exposition, and was given a stiff timeline: six months! It was completed the very morning that the exposition opened. When the exposition was concluded, the organ was moved to the Civic Auditorium. The city’s new municipal organist, Edwin Lemare, specified scores of tonal and mechanical changes that he required the Austin Company to complete upon re-installation. Of primary concern was the fact that the organ was being moved from a space that seated 3,000 to an auditorium with a capacity of over 10,000. The organ had many years of fame, but fell to near-obscurity in the late 1950s. In 1963, the Austin firm built a stunning black lacquer drawknob console. It saw a bit more use, but the horrific 1989 Loma Prieta earthquake rendered the organ silent. The organ sustained some damage due to falling debris. Funds were eventually allocated to repair and re-install the organ. The organ was returned to Hartford, and much work had been completed, but a few months into the project, a directive from the city ordered the organ to be returned to San Francisco. It remains in storage beneath the city, much like that final scene of Indiana Jones’s Raiders of the Lost Ark!

Opus 558 would be the company’s first five-manual instrument, built for the Medinah Temple (Masonic Lodge) in Chicago. This organ also had a sister stopkey console of four manuals. During this period, the company production averaged over 60 new pipe organs a year! The next major instrument would be for the Eastman Theater (for the Eastman School of Music); Opus 1010 was a unique theatre organ—the largest ever—of 229 stops! It was, sadly, removed in the 1970s. There were additional notable instruments during this time: the University of Colorado received a four-manual, 119-stop instrument in 1922. The Cincinnati Music Hall awarded a contract for Opus 1109, an 87-stop instrument that utilized much of the existing Hook & Hastings pipework. Opus 1416, a four-manual instrument of 200 stops, was built for the Sesquicentennial Exposition in Philadelphia. The final large concert hall organ of this period, Opus 1627, four manuals and 102 stops, was built for Hartford’s own Horace Bushnell Memorial Hall in 1929.

By the mid-1920s, Austin Organ Company was producing over 80 new pipe organs annually. This trend continued until the crash of 1929 and ensuing depression era. The company soldiered on, a bit weakened because of the lack of new business, tremendous overhead (the factory was expanded over three times from its original footprint), and company financing of new instruments to churches, from which payments only dribbled in. In July 1935, The Diapason published the announcement that the Austin Organ Company would close its doors. Non-specific Austin assets and raw materials were sold, and remaining contracts were completed (the final A.O.C. contract was number 1885). A few folks remained to complete warranty work and move the Austin tools and machines into storage. At this time, young Frederic Basil Austin and long-time employee Harold Dubrule kept the fires burning by completing some small rebuilds and service jobs. It was this association that inspired John T. Austin’s nephew to consider purchasing the company, a process that was completed in 1937.

The second Austin milestone: 1937—reorganization and move into a new facility

The “new” Austin Organs, Incorporated opened its doors in February of 1937. The transition from the old management to the new Austin was as seamless as could be expected. They were able to return most employees to their workstations, however, in a scaled-down facility located directly behind the behemoth structure that had been home to the company for the previous 36 years. For the first few years, the company leased the property from G. F. Heublein & Bro. Distributors—liquor distributors for much of the East Coast, famous for their pre-mixed “Club Cocktails.” A wooden guard mounted to an ancient band saw that is still in service in the Austin mill is actually a trespassing warning sign from the pre-1937 Heublein days. Within a few years, the property was purchased by the Austin corporation, and over the next three decades the buildings were expanded several times.

The original factory was rather foursquare—four stories, small footprint. Then a separate wood frame structure was built that served as an erecting room, then a fire, then the mill and new brick erecting room, additions to the main building that became pneumatic departments, more voicing rooms, console and cabinet shop, etc. The design department and metal pipe shop grew along the railroad tracks, requiring the private rail siding to be moved. In the late 1960s, the final addition was the large shipping/receiving and casting room. This expansion required a somewhat more adventurous move: purchase of land from the N.Y./N.H. & Hartford Railroad. Somehow, it was pulled off; the centerline of the main rail appears to have been moved slightly north, and the siding was completely eliminated. The sprawl of the factory now reached nearly 50,000 square feet. Sometimes it was not enough, but it is as efficient as any multi-story manufacturing space can be.

A charming, vintage Otis elevator allows safe and uncomplicated material transport between floors. Systems throughout the factory are up to date, and have been carefully maintained by conscientious staff and the foresight of F. B. Austin’s son, Donald. Assuming the role of president in 1973, Don was a formidable figure in the organ industry. He was a very private person, well respected by his colleagues and employees. Aside from his devotion to the company and care of the physical plant, he maintained the Austin tradition of assiduous design trends.

The well-regarded voicer, David Broome, who retired as tonal director at Austin in 1998, describes the “Austin sound” as never one of extremes. Austin has, as he expresses it, not traditionally been a leader in any new tonal movement in organbuilding. That being said, the company has always built a well-balanced chorus. Even instruments from the 1930s, when so many of our hallowed builders (now gone) built the most tubby-sounding diapason choruses, one can hear the gentle articulation and effects of moderately scaled Austin pipework. We can argue about the sound of the vintage Austin trumpets and oboes, etc., but we never find reeds like them—they not only remain in tune, but have good, steady tonal color as well. The construction of reed pipes was just one of the more than four dozen patents that the Austin Company was granted through the years.

The company motto—Scientia Artem Adjuvat—was not just a clever marketing concept for the Austin family; it was a way of life. Many of the machines in the factory that are used for Austin were made right here. So, we have the machines that repair the machines, right here in the factory! The now famous seven-headed monster that is used to build pedal and stop action blocks was originally built in the front building, and moved here in 1937. It has been improved several times, most recently this year when we added new bushings and guides to allow the belts to travel and run their saws and drills efficiently. (Rafael Ramos, who has been mill foreman since the 1980s, states that it now runs faster and smoother than ever before.)

In 1999, Don Austin retired from active participation in the daily operation of the company. He appointed his daughter Kimberlee as president. He continued as CEO until his death in the fall of 2004. In early 2005, Kimberlee Austin resigned her position with the company.

On an otherwise pleasant Monday in March of 2005, I received a phone call from Trinity College Organist John Rose. He told me that as of that afternoon, the Austin Company would be closing its doors. I was shocked. It felt as though my slightly peculiar but lovable old uncle had passed away. (We were at that time competitors, of course.) We wondered how in the world this could happen. Austin was always so . . . solid. The truth of the matter was that, in fact, the company did not “close”, but just temporarily ceased manufacturing new organs. There was no bankruptcy, no liquidation of tooling or assets. Don Austin’s wife, Marilyn, retained the services of business consultants; the result of their consultation was basically a public offering in the form of a letter sent to nearly every organbuilder or supplier in the country, while Marilyn and a few employees kept the phones answered and made small parts for existing instruments.

The third Austin milestone:

2007—a new direction

In the late 1960s, Richard Taylor, a former Aeolian-Skinner employee and New England Conservatory graduate, arrived at Austin Organs to assume the position of the soon-to-retire Les Barrows, who had been purchasing manager for 59 years. After a couple of years working in the plant and in the service department, the day finally arrived when he would occupy a small desk in the corner of the factory offices on the second floor. At the rather generous rate of $2.00 an hour, he was fairly pleased with his position. In the early 1970s, there was a brief drop in organ sales, and Don Austin decided to cut back in every department. He decided that there was no need for a purchasing manager. So, Mr. Taylor moved on to other industries, among them, purchasing manager–military operations for Colt Firearms. By the late 1980s, he had returned to organbuilding, as superintendent at the former Berkshire Organ Company in Western Massachusetts.

As for me, I have studied engineering in Springfield, Massachusetts, music at Westminster Choir College, and Emergency Medicine at Northeastern University. I had attended two seminaries, and for a short time was a novice in a small Franciscan religious order. Leaving all that behind, I applied science to music, and was working with Berkshire Organs in its final years, where I discovered the absolute wonder of the technology that transmits music from the organist, through the console, windchests and eventually evokes sound from the pipework.

Following the demise of Berkshire Organs in 1989, we formed American Classic Organ Company. While remaining a modest-sized operation, we completed several new instruments and built a respectable service business. We located the workshops in sleepy Chester, Connecticut in 2000.

We came into the Austin picture during the summer of 2005. Through a series of events, we received a letter proposing financial investment or purchase. After several weeks of soul-searching and discussions, we were able to come to an agreement. In January 2006, we purchased the assets and liabilities of the company. Almost immediately a dozen employees returned to their benches, sales representatives arrived back at the door, and the company has begun to rebuild. Several new people have since been added to the roster of Austin employees. The new management aims to build team spirit, stay nimble, and remain rational in the face of terror!

Among the projects completed this year have been dozens of action orders for existing Austin organs (often delivered ahead of schedule). We designed, built and delivered a mahogany four-manual drawknob console in 62 days. It was constructed on the traditional Austin steel-frame system. We completed a major project on an instrument in Lansing, Michigan, which required a new console, utilizing the existing (stripped and refinished) casework, re-actioning, and some tonal additions. A new instrument, Opus 2790, will be installed this coming Easter. This contract was negotiated within a few weeks of restructuring. Several interesting projects are pending for 2007. The metal pipe shop has completed new pipework for the new organ on the floor right now (Opus 2790) and other Austin projects. We have also recently completed extensive repairs and historic renovation on several sets of vintage Aeolian-Skinner pipework at the Mormon Tabernacle. We continue to cast our own pipe metal, and manufacture both flue and reed pipes.

The company is celebrating the milestones of 114 years since the first Austin organ was built, and 70 years since reorganization and move into the current factory. We are on solid footing and in good shape to complete projects large and small, with confident vision of significant growth and expansion.

In quiet moments around the factory, you can hear the faint, yet distinct footsteps of John, Basil, F.B., and Don Austin, as their spirits permeate every process and instrument. The memories of so many gifted and wonderful people who have literally spent their lives here continue to affect our days. They are all a constant reminder of our commitment and challenge to continue Austin’s heritage in American organbuilding. We are humbled to bring new life into this venerable institution, and the many calls and notes we receive encourage us to move forward to celebrate whatever might be the “next milestone.”

—Michael Brian Fazio